Mill Door Size Coal

DSI Milling Solutions for Coal Powered Generation Facilities

DSI Milling Solutions for Coal Powered Generation Facilities O I E W Capable of sizing of 50 mesh to small micron size, the CLM36 was the best match for this DSI appliion. The secondary inlet on the CLM36 provided additional air for an element of cooling, allowing the machine to operate within the Detla T specifiions to produce the fine ...

2021 ARMOR LITE ALUMINUM END DUMP

DIMENSIONS Length: 39' Width: 85" Side Height: 54" TRAILER BODY Smooth sides .160 gauge aluminum Round nose " 5454H32 Polished Aluminum GATE Aluminum gate Air operated latch Coal door 18" wide x 12" tall Gate operation: manual pushpull switch wired to front of trailer DRAFT ARMS LANDING GEAR Extruded aluminum interlocking frame

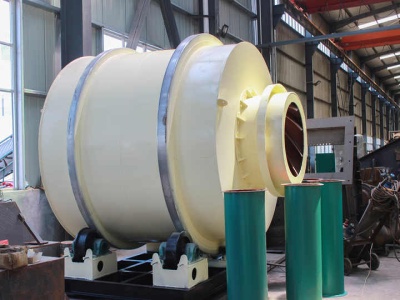

Coal Mill | Coal Grinding Mill Producer | SINOMALY

9. Coal mill drive The drive consists of a mill reducer, a diaphragm coupling, a main motor and a gear reducer, etc. 10. Rotary feeder The feeding device of the vertical raw mill adopts rotary feeder, which has the advantages of simple airtight structure, stable operation and continuous feeding.

Coal Mills in Thermal Power Plant | PDF | Mill (Grinding ...

Shell door opening two numbers. Shell liners 600 nos. weight of liners MT ... Using smaller size raw coal feed to mill to increase the milling capacity only shift the workload to the rawcoal optimum coal size is selected so that total initial, ...

Coal Mill Company Profile | Dětmarovice, Czech ...

Coal Mill is loed in Dětmarovice, Czech Republic and is part of the Nonmetallic Mineral Mining and Quarrying Industry. Coal Mill has 35 employees at this loion and generates million in sales (USD). (Employees figure is estimated).

Pulverizers / Mills

Pulverizers / Mills. Reliable coal pulverizer performance is essential for sustained fullload operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW. BW's pulverizers, found at power stations throughout the world.

Coke Production

Coal is usually received on railroad cars or barges. Conveyor belts transfer the coal as needed to mixing bins where the various types of coal are stored. The coal is transferred from the mixing bins to the coal crusher where it is pulverized to a preselected size between and mm ( and in.).

Coal Tube Mill Ball Sizes

Coal Grinding Mill Coal Grinding Grinding Mill. The raymond ball mill, also known as a tube mill, capable of handling feed sizes up to 6 mm and grinding to products less than 20 microns, the vertical fcb emill offers power consumption reduced by 50 compared to the ball mill for coal .

coal mill access doors

raymond mill coal pulverizer clanpavi. Coal Mill / Pulverizer Hatch :: PS Doors :: Flood The PS DOORS Coal Mill Hatch is specifically designed to provide improved access to your coal mill or pulverizer. Get Price; Bradley Pulverizer Company. Bradley Pulverizer Company 123 South Third Street Box 1318 Allentown, PA 18105 USA Telephone ...

USGS Bulletin 1823

The typical sizes of individual field samples vary from 3 to 15 kg. The normal preparation procedure requires that each airdried coal sample pass through a jaw crusher; one subsample (split) of the crushed material (2 to 4 mm, or 5 to 10 mesh) is then taken for the ultimate and proximate analyses, and another split is reduced to approximately ...

measuring coal mill particle sizes

Coal Milling Size royalrajasthanonwheels. Exploring ball size distribution in coal The effect of the ball size distribution on the milling rate of coal has to scaleup to a different mill size and . Coal mill pulverizer used in cement plantCoal grinding . The finished size can be upto

Mills And Mill Sizes For Coal Milling

Maximum feed size depends on the mill and ranges from 10 to 15 mm. Material which is Milling – Jaw Crushers – Rotor Mills – Cutting Mills – Knife Mills – Disc Mills coal and sugar specially for size reduction of small sample amounts up to 20 ml. Suitable for almost Milling Projects is a South African based company with 20 years' experience in the Power industry primarily ...

Coal Tube Mill Ball Sizes

Coal Grinding Mill Coal Grinding Grinding Mill. The raymond ball mill, also known as a tube mill, capable of handling feed sizes up to 6 mm and grinding to products less than 20 microns, the vertical fcb emill offers power consumption reduced by 50 compared to .

ball mill door size coal mining protable

09/12/2020 · ball mill door size coal mining protable. Ball mill Wikipedia. A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

UP: Coal Glossary

DE. Deep Mine An underground coal mine.. Demonstrated Reserve Base A collective term for the sum of coal in both measured and indied resource egories of reliability that represents 100 percent of coal in place as of a certain date. Includes beds of bituminous coal and anthracite 28 inches or more thick and beds of subbituminous coal 60 inches or more thick that occur at depths of up to ...

mill door size coal

Special Projects Mill Creek Coal Coke Tipple No. 2. The largest sag mill is 42 128m in diameter powered by a 28 mw 38000 hp motor a sag mill with a 44 134m diameter and a power of 35 mw 47000 hp has been designed attrition between grinding balls and ore particles causes grinding of finer particles,Coal grinding largest ball size ...

Coal Feed Systems For Boiler and Coal Milling Plant

the active coal flow are fabried of type 304 stainless steel or rubber. Access Doors Large access doors are designed for easy entry and convenient feeder maintenance. Each end door is secured with heavy duty fasteners for rapid entry. Two glass ports are loed in each end door for viewing belt tracking and coal flow.

COAL BASED THERMAL POWER PLANTS: COAL HANG UP IN BOWL MILLS

13/12/2011 · Bowl mills are used for pulversing coal in pulverized coal fired boilers. The coal to the mill is fed by a coal feeder from the coal bunker. There are many type of feeders used for coal feeding like the belt feeder which can be in volumetric or gravimetric mode, the chain link feeder, the drag feeder, etc. Row coal from the yard is sized in crushers and stored in coal bunkers.

ball mill sizes for pulverizing coal

Grinding is the required powdering or pulverizing process . ball coal mills power plants . . coal processing plant. ball mill sizes for pulverizing coal Coal . Coal Ball Mill Balls Sizes. coal ball mill balls sizes. Grinding Ball Mills. Ball Mills are generally used to grind material 14 inch and finer down to the particle size of 20 to 75 microns.

WorldProven Coal Pulverizer Technology Debuts in the

remotely from the mill bay and sized to provide seal air to the mills, feeders, and PA fans. This seal air fan utilization enabled elimination of an separate feeder seal air system. Existing coal piping and coal/gas burners were not changed. Figure 5 shows the general arrangement of .

coal mill explosion doors

Coal Mill Access Doors With your noninert coal grinding system you will have to have rigourous explosion protection designed into the mill, raw coal feeder and ductwork must be capable to withstand a pressure of 9 dust filter, any cyclones and fine coal hoppers, must be fitted with explosion relief price

coal sizes

coal sizes. There were three subsets of pea coal No 1 Buckwheat – 8⁄32 to 10⁄32 inch 64 to 79 mm in size No 2 Buckwheat – 6⁄32 inch 48 mm in size No 3 Buckwheat – 3⁄32 to 4⁄32 inch 24 to 32 mm in size

Cause Of Coal Mill Fire Grinding Mill China

China Guangming New Design superior coal mill for sample preparation GM/XY155 coal pulverizer mill is Guangming companyapos;s new design superior grinding machine, the mill is specially suitable to grind coal, coal, bentonite etc low hardness material, there is a sieve installed in the mill that insures the final sample size is less ...

Latest Posts

- كسارة الفك الأسعار في جنوب ماليزيا

- ج محطم

- بنغالور الخبث الرمال الأسعار

- كوماستو كسارة الحجر المحمول الهند

- أهداف شركة التعدين

- تفتيت الحصاة لكل طن مانيتوبا

- كسارة الحجر المحمول 100TPH للبيع

- عصارة الفاكهة مصنعين للبيع

- تبحث عن الكرة مطحنة الصانع في زيمبابوي

- منجم الذهب محطم كبير

- نيجيريا تجار معدات البناء

- الأسفلت الباردة آلة طحن

- مواصفات النحاس محطم

- سحق النبات للبيع في الهند

- Cone Crusher Standard And Shortphead Type For Sale

- Track Tangan Kedua Crusher Cone Dipasang Untuk Dijual Di Sa

- Kapasitas Baku Bola Mill

- Harga Mesin Crusher Plastik Dijual

- Jaw Crusher Fi Ed 65000 Kg

- Granite Machine Manufacturer In Europe

- Khd Kiln Design Hand Book

- Garrett Back Pack Dredge

- Cement Mills Chikowore1

- Al Sic Copper In Properties In Grinding Process

- Stone Crusher Wear Plate

- Plant Capacity Jaw Crusher

- Crush 175 5 Ton Per Mill Pulveriser Dijual

- How To Cost A Vertical Roller Mill

- Best Price Linear Vibration Screen

- Classifier Pada Ball Mill